History of Harwill Incorporated

Parent company of Aero Craft Boats

This section of my website is dedicated to Harwill and all it's former employees that worked for my dad (Tony Harkins) and my uncles. I can recall many Saturdays going with my dad down to the "boat works" and watching him make sure everything was secure.

Date: 22

April 1956

Source: The

Flint Journal

Subject: Aluminum

Boat Pioneers in St Charles

Decade

Old

Author: Harold

Bastien (Journal Outdoor Writer)

There

are no conveyor assembly lines in the plant of Harwill Inc., at St Charles,

where Aero-Craft aluminum boats are made-at a rate of 200 a week.

All

the parts, and the completed boats themselves, are so light they are moved by

hand, by women as well as men.

It

is this lack of excessive weight that has bought about the tremendous boom in

aluminum boats in the ten years since Harwill built the first production craft

made of the light but tough metal.

This

year may be the biggest for the boating industry, and Harwill, which employs 100

residents of the little Saginaw County town, expects to capture it’s share of

the market. Its large stockpile of winter made boats and canoes is

dwindling rapidly as huge loads leave the plant each day.

There

are many reasons for the popularity of aluminum boats, with lightness at the top

of the list. Durability is a big factor. The only wood is

on the transom, with plates of marine plywood riveted inside and out to

accommodate an outboard motor, or motors.

All

seams are caulked and fastened with airplane rivets, closely spaced. There

are no floorboards to add to the weight, passengers walking right on the bottom,

which is covered with non-skid paint.

All

this makes for easy maintenance, and permits the company to guarantee it’s

products against puncture for 20 years, tops among all companies making this

type of boat.

When

spring comes, all one has to do is put his aluminum boat in the water. There’s

no scraping, caulking and painting. Under each seat is Styrofoam to

provide buoyancy.

Harwill,

Inc. had it’s beginning in the brains of three men- L.B. Harkins, Leon

Harkins, and Doug Wiltse. All had a background in aircraft sheet

metal design and fabrication.

They

chose to incorporate because it was necessary to sell stock to raise enough

capital to begin operations. The names of the three men were combined

to form the corporate name, Harwill, and the new company came into being March

4, 1946.

A

form letter was sent to about 50 villages in Michigan, asking about what

concessions could be granted to induce Harwill to locate it’s plant to the

best advantage. The letter stated the company needed a building and

that it planned to employ about 10 persons within a year.

The

best offer was made by St Charles, which had an abandoned water plant which

could be converted into a factory.

During

the conversion period, Harwill’s founders designed Aero Craft model A, and a

pilot model was ready for testing early in June 1946. After a few

minor changes the model was put into production early in July, and the first

aluminum boats began to roll off a production line, the beginning of a brand new

industry.

By

the fall of 1946 the demand for the new boat far exceeded Harwill’s capacity. Many

of the manufacturing operations were being performed outdoors, and winter was

approaching. A new issue of stock was offered and the additional

plant space and equipment permitted an increase in production from 20 to 50

boats a week.

Only

a year later, Harwill reached a new milestone when it began production of it’s

18 ˝ foot Model JCC, America’s first outboard cruiser to come off an assembly

line.

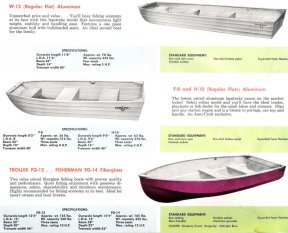

Harwill

has expanded continuously during its first decade. New models have

been added each year and now there are 29 listed in the company’s catalog,

ranging from easily handled nine-foot runabouts with a weight of 65 pounds, to

the big cabin cruiser, which weighs 585 pounds. In between are two

canoe models weighing 67 and 69 pounds, and boats of various lengths and styles

and weights.

Although

pleasure boats are the company’s principal product, it has been used for

production of motor freight truck trailers, aquaplanes, toboggans and military

production of aluminum power and assault boats, parachute packing tables, mess

tables, folding tables and ship cabinets.

L.B.

Harkins is the General Manger. His brother, Leon, is Production

Manager and Treasurer, and Doug Wiltse is the Secretary. A.S. Brennen,

Saginaw insurance executive is the President, serving in an advisory capacity,

and is active in the company’s financial relations. L.B. Harkins

had experience in aircraft conduction with United Aircraft and Briggs Aircraft

in Detroit and Dow Chemical Company in Midland Michigan. He is the

author of “Magnesium Fabrication”, published by Pitman Publishing in 1947. Wiltse

was his co-worker in Bay City Michigan before Harwill was organized. Leon

Harkins was manager of the Williams Form Engineering Company in Grand Rapids.

[Note…Reprinted exactly as written, with the exception of grammar corrections.]

Harwill Incorporated, 1946. This is the old waterworks building, later used as the Halloween Haunted House.

Founded originally by LB Harkins, Leon Harkins and Doug Wiltse, additional capital was raised in 1948 by a stock offering and several local businessmen and a third brother, Tony Harkins invested. Local insurance agency owner, AS Brennan became president by virtue of his investment, while LB was General Manager, Leon Harkins became Treasurer and Tony Harkins became Plant Superintendant. A fourth brother, Mort Harkins was the fiberglass manager.

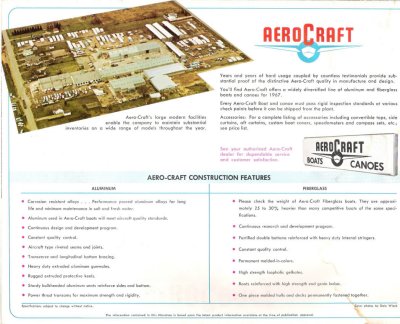

New facilities were built in 1947 on an eight acre plot at 400 Water Street to specifically manufacture both aluminum and fiberglass boats and various items for the US Government.

In the early part of 1969, the firm was sold to Browning Arms and became the Browning Marine division. Operations continued until the economy and other factors forced them to cease operations in mid July 1974.

Shortly thereafter, the operations were sold to Fuqua Industries and Browning Aerocraft restarted operations .

In 1979, operations were moved to lower cost Indiana but soon thereafter, the company was liquidated.

In 1980, a different company moved operations to St Charles named Thompson Boats. For approximately twenty years, it operated before shutting the facilities both on Water Street and a newer facility located north of St Charles on North Saginaw Street.

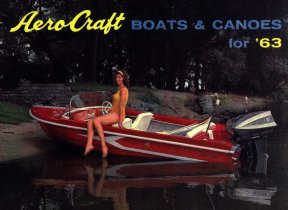

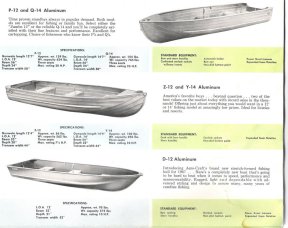

Aluminum offerings. Aerocraft matches. Operations at it's peak, late 1960's.

Aluminum offerings.

Additional pictures